- Global

- Austria

- China

- Czechia

- France

- Germany

- Great Britain

- Italy

- Mexico

- Netherlands

- Poland

- Slovakia

- Slovenia

- Switzerland

- USA

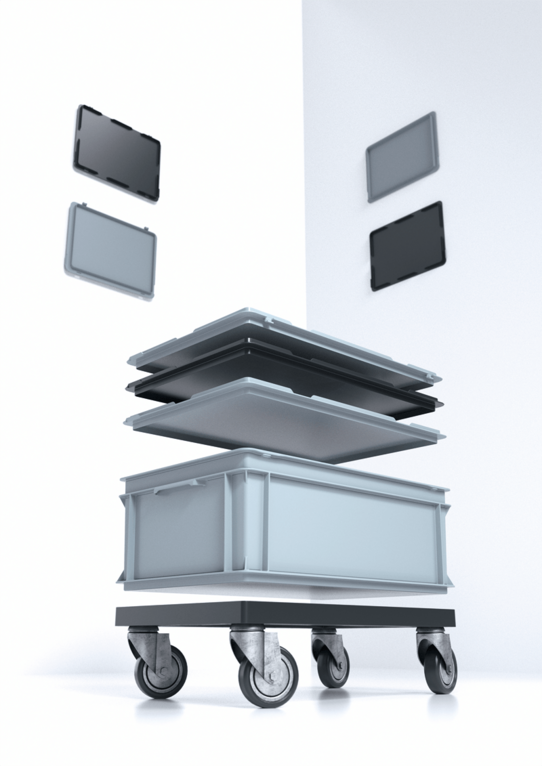

Stackable containers

Standard products

The right solution for every purpose

Stackable containers are still often the right solution approach in reusable logistics today

Stackable containers from Utz are characterized by robustness and modularity. Different formats can be easily combined and joined together to form units. As a result, they are ideally suited to the different logistics standards in the transport industry worldwide.

Several customer solutions have become standards over the years, which Utz customers use today across all industries.

RAKO means "frame construction". The RAKO was Utz's first stackable container for industrial use. It forms the technical basis for many of Utz’s stackable containers.

A variety of options

The RAKO also offers different base, side and handle options, which can be combined with each other. This results in a total of

350

RAKO

variations

More examples from the world of stacking containers

KLT, small load carrier for the automotive industry

The standardized VDA-KLT-container series are specially tailored to the logistics processes in the automotive industry. Utz was involved in the development of the modular container families from the very beginning and, as a certified manufacturer, offers you the corresponding KLT containers and accessories in accordance with the official country-specific recommendations (including VDA, AIAG).

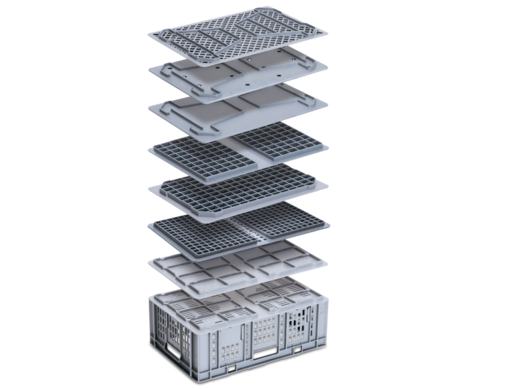

SGL - The standard in the flow of goods

"SGL" stands for "Schweizerische Gesellschaft für Logistik", today GS1. Among other things, the SGL guidelines serve the purpose of standardizing reusable plastic containers and creating the conditions for containers to be interchangeable. These requirements are met by the SGL stacking containers from Utz.

Thanks to the ribbed, perforated bottom or the bottom with grid, a high air circulation is guaranteed. All SGL bases allow safe compound stacking of one container 600 x 400 mm over two containers with basic dimensions 400 x 300 mm.

EUROWAVE

EUROWAVE is a container system for your daily storage and transport tasks in business and leisure. Equipped with many good Utz features: Clever with easy handling and stable structure. Creative with a dynamic profile. Sustainably produced from certified secondary raw material.

Accessories and extras

Barcode (frames), Transponder / RFID chips and in-mould labels can be positioned individually.

Two- or three-sided rim

Hot stamping

Pad printing

Thermal printing

Screen printing

Font inserts

In-mould labelling

Foil stamping

Laser marking

© Georg Utz Holding AG