- Global

- Austria

- China

- Czechia

- France

- Germany

- Great Britain

- Italy

- Mexico

- Netherlands

- Poland

- Slovakia

- Slovenia

- Switzerland

- USA

Pharma and med tech

Returnable, reuseable logistics & transport packaging

Pharma, cosmetics, chemical, and med tech applications

Utz Group partners with many of the world’s leading pharmaceutical, medical device, and cosmetic brands to bring efficiency to their automated process. We reduce their supply chain costs and enhance safety by utilizing reusable transport packaging solutions.

We primarily develop customized solutions made specifically for your manufacturing operations, storage and logistics needs. In addition, we also have an extensive line of standard products.

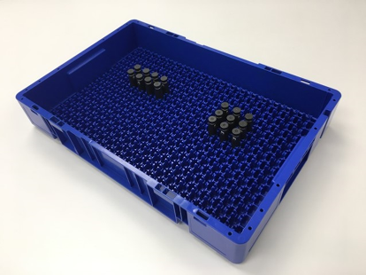

Assembly of medical devices in Utz trays

Trays in use across all production stages

For globally operating pharmaceutical and medical technology companies, Utz has developed trays that run automatically through the entire supply chain. Upstream suppliers have the trays automatically filled with individual medical device parts. After final assembly, the medical devices can be temporarily stored in additional trays before they are automatically removed, packed, and shipped.

High precision guarantees process reliability

The use of high-quality approved materials and close quality control ensures that the proper requirements are met for your processes. We offer material and load tests that can be carried out during production guaranteeing consistent results.

Pharma packaging solutions from Utz

Utz Group products fall in 5 different types of packaging during end-to-end product development, product lifecycle, supply chain and delivery.

1. Secondary packaging

2. Tertiary packaging

3. Intermediate processing

4. Storage & warehousing

5. Logistics & shipment

Products & expertise

We are fully compliant with all international standards guiding the Pharma & Med Tech industry.

Depending on the specific applications or usage, we can provide necessary documentation or include additional steps to meet your regulatory needs.

Selected customizations for pharma solutions

Standardized frame contours

We offer standardized frame contour of our trays, making them universally applicable and suitable for all stages of production.

Individual receiving nests

Need to change which products your trays are handling? Not a problem. By simply changing the tray base, we can accommodate any product updates you have, guaranteeing efficiency and adaptability in your supply chain.

Color coding

We can easily implement color coding into our products so they can be clearly identified in your processes.

Recyclable

Utz only uses single-grade plastics which are fully recyclable. These plastics can be used almost indefinitely and are suitable for recycling.

7 reasons to choose Utz

75

years of global experience

500

pharmaceutical and med tech organizations trust in us

5000

solutions ensure safe delivery of your pharmaceutical products

Looking for a custom solution?

We'd love to talk to you. Our experts will cover your individual needs and develop a solution matching your requirements.

Request for consultation© Georg Utz Holding AG