- Global

- Austria

- China

- Czechia

- France

- Germany

- Great Britain

- Italy

- Mexico

- Netherlands

- Poland

- Slovakia

- Slovenia

- Switzerland

- USA

Custom made reusable packaging

Individual Solutions

Customized packaging solutions

A small but significant difference

Efficiency is the key in today’s logistics. Ergonomics, full protection, maximum load, volume and identification are all small but significant factors.

Utz solutions can be customized giving you containers, pallets and trays which are tailored to your processes. The benefits of which can be for example reduced fuel costs and damage reduction. When reusable packaging is tailored to your companies needs not only does it become an integral part of your logistics processes, the payback is significant.

Individual reusable packaging

Curbside pickup at supermarkets with DOLLYFIX – a flexible transport system

Online shopping continues its lead of the consumer goods industry. New challenges are therefore constantly arising in retail the “last mile". With curbside pick up at many supermarkets, customer orders are automatically assembled and made available for collection at the selected time. When empty, containers are stacked inside each of each other, 70 percent space saving is achieved.

The DOLLYFIX concept is the perfect answer to completely new types of processes in semi-automatic curbside supermarkets and has been successfully implemented by several customers.

The All Encompassing - GS1 SMART-Box packaging concept

Efficiency comes from standardization and modularity. Based on a precise analysis of the supply chain of various producers and retailers from the pharmacy sector and GS1 Germany, Utz has developed a new packaging concept: “GS1 SMART-Box”.

With the help of this new family of collapsible containers, handling costs can be minimized from production to the point of sale, saving on disposable packaging. The container system offers the following benefits: volume-optimised return, automated load handling, concise size options, digital recognition, transport locking and numerous other features. This enables customers to cut their process costs by more than 40 percent and at the same time reduce the CO2-footprint by up to 80 percent.

The Utz ECOBIN: An award-winning workplace container with many functions

The Böllhoff Group is one of the world's leading manufacturers and distributors of fastening elements and assembly systems. ECOSIT® stands for "ECOnomic Supply In Time". With this service package, Böllhoff handles the complete supply chain for its customers: from planning, procurement, quality inspection and warehousing to the distribution of goods to the assembly line. The containers of different sizes fit perfectly into each other and can be stacked to save space. Thanks to modern RFID technology, the boxes can be integrated into digital process chains in a contemporary and future-proof manner. In this way Böllhoff ensures the permanent availability of all items, to the complete satisfaction of the customer.

We are constantly working on the optimisation of our supply chain solutions with the aim of offering the most efficient procurement and delivery systems possible. With our latest product “ECOFREIGHT”, for example, we have been able to establish an innovative transport concept that ensures particularly safe and sustainable goods transport. The focus is on the multiple award-winning small load carrier “ECOBIN”, which Utz developed and designed in close cooperation with Böllhoff” - Mario Grassy, Innovations Manager at Böllhoff

Modular packaging solutions

With the combination of precise component holders and containers as well as pallets from the Utz product range for various industries, they create the right individual transport unit for their specific products.

Modular manufacturing concepts, high-precision machining, proprietary materials and the latest marking technology allow for maximum variant diversity.

Modern thermoforming trays

Utz component holders are designed for automated part removal and digital integration into the customer's processes. Utz basic frame concepts can be adapted to the packaging solution of their parts with little effort. All 8 Utz sites use uniform standards for thermoform tray design. Utz trays can thus be combined in a modular way.

Bespoke Products – Matched Perfectly

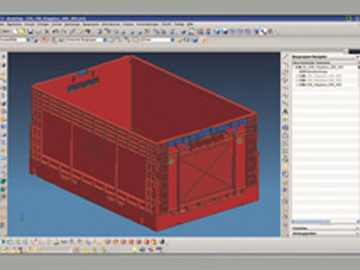

With the help of various analysis methods, we calculate components digitally and subject them to various real-life simulations. This permits the simulation of load calculations and applications as well as the flow behavior of the plastics, which significantly shortens development and test cycles. Practical feasibility is simulated during the design phase.

All from one – Concept to finished product

Utz creates smart customized solutions. Starting with the initial idea right through to the finished product. Engineering, sales and production work together to achieve this. Our experienced customer solution advisors, all with specific industry knowledge, will talk you through feasible concepts and solutions. In taking a concept from design to full production you will benefit from Utz technical knowledge, in design, raw materials and tooling to gain full production optimisation.

From design to product

The idea and 3D modelling

We match your requirements with our know how and our proven methods to assemble your product. We use CAD and 3D modelling so in a short time you will see first drafts of your solution.

Rapid prototypes and model construction

With accurate models and rapid prototypes, we can produce a tangible product likeness early in the process, allowing highlighting of details and accuracy at an early stage. This not only saves time but lessens the need for costly tool modifications later. As the customer, it is you who has the final say.

Utz product in series production

At Utz, we design the tools for series production ourselves per customer requirements. No matter whether you need 10,000 or 1 million parts, our qualified Utz employees know the right tool concept, without any need to compromise on quality.

© Georg Utz Holding AG