- Global

- Austria

- China

- Czechia

- France

- Germany

- Great Britain

- Italy

- Mexico

- Netherlands

- Poland

- Slovakia

- Slovenia

- Switzerland

- USA

75 years of Utz

75 years of experience

Family and values

The Utz corporate values are still largely based on the ideas and principles of our founder, Georg Utz, and his wife Martha Utz. Growth by our own efforts, striving for the highest quality and maximum customer benefit, combined with the family ethos and a high sense of responsibility towards employees and society. As a family business, we remain permanently committed to these values to this day.

Circular economy

Sustainability was part of our founder’s original plan for the company and has since become part of our DNA. We act with foresight from the start and integrate the sustainable use of limited resources and recycling at the end of the product life cycle into our strategy. He recognized early on that he was on the right long-term trend with consistent focus on reusable products. It is therefore not surprising that the first Utz plastics recycling plant was put into operation in Bremgarten at the beginning of the 1970s and is maintained to this day.

Customer orientation

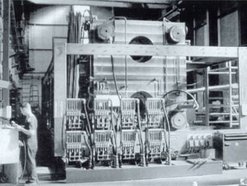

In the seventies, the development of customer-specific containers is added as a new business area, the cornerstone of our current core business. In general, the demand for large-volume plastic containers such as pallets or paloxes is growing. For this reason, the Mannesmann company manufactured exclusively for Utz what was then Europe's largest injection molding machine with a processing weight of up to 50 kg of plastic. At this time, Georg Utz AG ventures its first step into nearby foreign countries and founds the subsidiary in Schüttorf, Germany.

International expansion

In the following decades, Georg Utz AG gradually evolves from a producer of standard products to a manufacturer and service provider for customized solutions. It is therefore a logical step for Utz to follow its customers to their locations in order to ensure joint development, production and quality control on site. Over the years, further subsidiaries were added.

Our history

1947

Switzerland

Founding of the company Georg Utz, toolmaking in Zurich Höngg

1948

Switzerland

Move to Zurich Altstetten to larger premises

1953

Switzerland

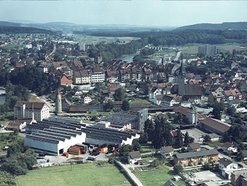

Relocation to Bremgarten with 16 employees. Series production of zig-zag devices for sewing machines.

1955

Switzerland

Company restructuring into Georg Utz AG

1957

Switzerland

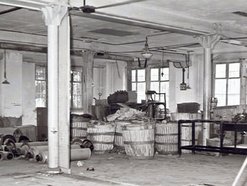

Purchase of the “Honegger” silk weaving mill and the entire company premises (50,000 m²)

1958

Switzerland

First injection moulding machine with 40 gram shot weight

1965

Switzerland

Start of production with storage containers, start of the RAKO series

1971

Germany

Founding of the subsidiary Georg Utz GmbH in Schüttorf

1972

Switzerland

New company building and expansion of the machine park to 30 injection moulding machines

1973

Switzerland

Procurement of the then largest injection moulding machine manufactured in Europe with a clamping force of 3,000t and 52,000 g shot weight to produce plastic pallets and pallet boxes.

Purchase of the pallet mould for pallet 33 - 604

Construction of the new office building

1974

Switzerland

Construction of the first plastics recycling plant in Bremgarten

1983

Switzerland

Expansion of the logistics warehouse in Bremgarten

1985

Switzerland

Start of thermoforming production in Bremgarten

1987

Switzerland

First ISO certification

1988

Germany

Construction of two new silos

Construction of the administrative wing and production hall 2

Expansion of the external warehouse and tool shop

1990

Great Britain

Founding of the subsidiary George Utz Ltd. in Alfreton

1992

Switzerland

Construction of the recycling building in Bremgarten

1992

France

Founding of the subsidiary Georg Utz Sarl. in Bressolles

1995

Switzerland

Founding of Georg Utz Holding AG with head offices in Bremgarten

1996

Switzerland

Founding of the subsidiary POOLTEC AG, the service company for the management of returnable containers in Bremgarten

1997

Poland

Founding of the subsidiary Georg Utz Sp.z o.o. in Katy Wrocławskie

2000

Switzerland

New large parts production in Bremgarten

2003

USA

Founding of the subsidiary Georg Utz, Inc. in Columbus, Indiana

2005

China

Founding of the subsidiary Georg Utz Materials Handling (Suzhou) Co., Ltd. in Suzhou

2009

Russia

Founding of the Georg Utz Representative Office in Moscow

2009

USA

Completion of the new company building with production facilities at Georg Utz, Inc. in Edinburgh, Indiana

2012

Switzerland

New large-scale machine at Georg Utz AG in Bremgarten

2012

Germany

Completion of the new thermoforming hall at Georg Utz GmbH in Schüttorf

2013

Germany

Expansion of the administration at Georg Utz GmbH in Schüttorf

2013

Switzerland

New thermoforming hall at Georg Utz AG in Bremgarten

2014

Great Britain

Expansion of production and administration at George Utz Ltd. in Alfreton

2015

Great Britain

First large-scale machine at George Utz Ltd. in Alfreton

2015

Poland

Expansion of production and administration at Georg Utz Sp.z o.o. in Katy Wrocławskie

2015

China

Opening of own plant at Georg Utz Materials Handling (Suzhou) Co, Ltd. in Suzhou

2017

Switzerland

Opening of new building at Georg Utz AG in Bremgarten

2017

Mexico

Opening of own thermoforming production at Georg Utz de México S. de R.L. de C.V. in San Miguel de Allende

2020

France

Move to the new plant of the Georg Utz Sarl in St. Vulbas

2021

Mexico

Opening of own plant at Georg Utz de México S. de R.L. de C.V. in San Miguel de Allende

© Georg Utz Holding AG